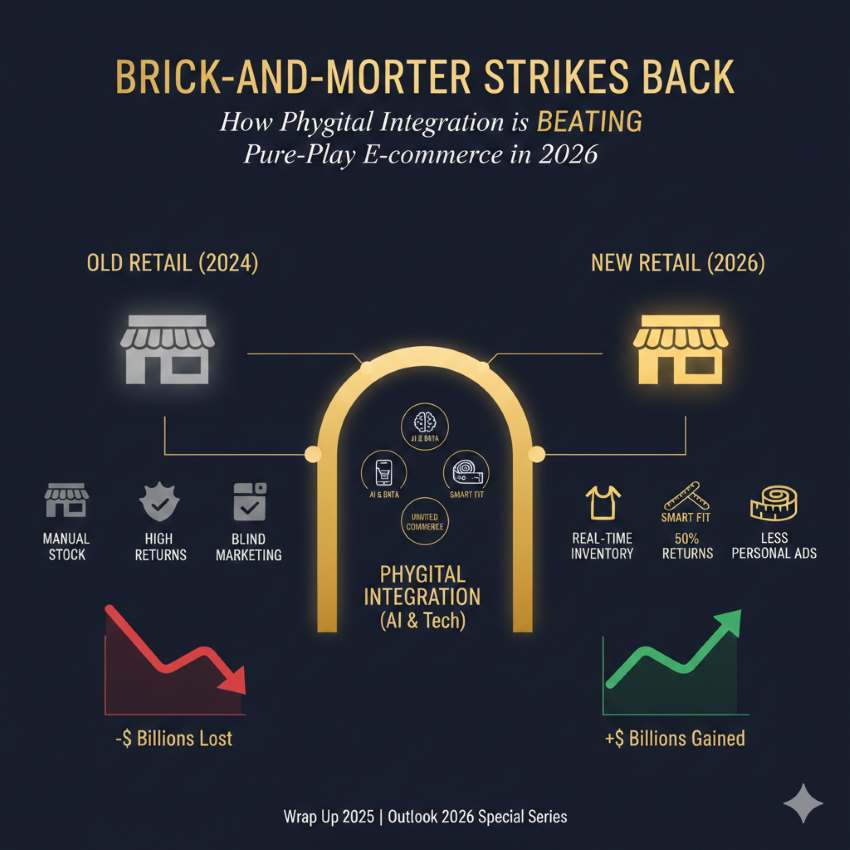

The global fashion industry is going through multiple levels of issues. Struggling sales, overflowing stockpiles, and unsustainable practices are just a few of the issues plaguing major brands. But a new solution is emerging: on-demand manufacturing.

Mass production, mass waste

Traditional fashion relies on made-to-stock, where vast quantities of clothing are produced based on forecasts. This often leads to overproduction, with unsold items ending up in landfills. Unsold items pile up in warehouses, or worse, get incinerated – as in the case of H&M burning 12 tons of clothes annually. This wasteful system also fuels a demand for cheap labor, with garment workers in developing countries facing exploitation. A 2022 study revealed the fashion industry is responsible for a staggering 10 per cent of global greenhouse gas emissions and generates 92 million tons of textile waste annually.

Making only what's needed

On-demand manufacturing flips the script. Clothes are produced only after a customer places an order, eliminating the need for guesswork and reducing waste. This reduces waste, minimizes stockpiles, and allows for smaller production runs. Imagine a world where your T-shirt is made specifically for you, not piled high in a distant warehouse.

However, promising, on-demand isn't without its hurdles. Big brands like Adidas experimented with customization with ‘miAdidas’ but faced challenges like longer wait times and higher costs. Consumers, accustomed to fast fashion's immediacy and affordability, weren't quite ready for the shift. Additionally, existing infrastructure geared towards large batches makes single-unit production impractical.

The rise of smart batches

The answer lies in a middle ground which is: small-batch production. Brands like Alohas and Asphalte are finding success with this approach. They manufacture closer to consumers, in smaller quantities, ensuring the right price and minimal waste. Indeed, small batches produced closer to the consumer, allows quicker turnaround times and competitive prices. This approach aligns with existing manufacturing processes, making it more scalable.

Shifting consumer culture

Tech startups are playing a crucial role. Companies like Unspun (micro-batch 3D weaving), Silana (robotic garment assembly), and Pattern Project (AI-powered production) are revolutionizing the industry. Additive manufacturing (3D printing) promises to minimize waste by creating garments as single pieces, eliminating the need for excess fabric and cutting scraps.

Shifting consumer mindsets is equally important. We need to move away from the fast fashion mentality and appreciate the true cost and value of clothing. Regulations like France's Anti-Waste law are pushing for change, but a deeper cultural shift is necessary.

On-demand manufacturing isn't a one-size-fits-all solution, but it offers optimism about a more sustainable and responsible fashion future. By embracing innovation, educating consumers, and working collaboratively, the industry can finally break free from its wasteful ways.