"Tailored Industry, Co-founded by Alex Tschopp, believes many knitwear brands today are forced to plan lengthy production cycles and undertake astronomically high order quantities which prevents them from launching new collections. Their chronic overproduction also results in vast quantities of unwanted apparel ending up in landfills which further compresses the company’s profit margins."

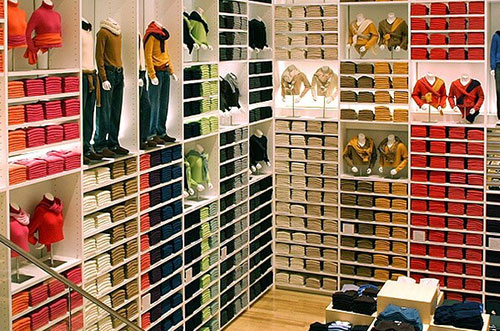

Tailored Industry, Co-founded by Alex Tschopp, believes many knitwear brands today are forced to plan lengthy production cycles and undertake astronomically high order quantities which prevents them from launching new collections. Their chronic overproduction also results in vast quantities of unwanted apparel ending up in landfills which further compresses the company’s profit margins.

Tailored Industry, Co-founded by Alex Tschopp, believes many knitwear brands today are forced to plan lengthy production cycles and undertake astronomically high order quantities which prevents them from launching new collections. Their chronic overproduction also results in vast quantities of unwanted apparel ending up in landfills which further compresses the company’s profit margins.

The company believes it is time to set a new paradigm in knitwear production by mixing hardware and software for an efficient and flexible output. Tailored Industry already raised $650,000, and plans to further raise another $1or $2 million through seed funding. This will help it to triple its five-person team over the next year by onboarding additional engineers, programmers and operators to keep its 10 Shima Seiki 3D knitting machines running smoothly.

A full-service solution from apparel production

The Brooklyn facility of the company manufactures around 1,000 to 2,000 units of knitwear apparels every month. It produces a range of styles including sweaters, dresses, beanies, cardigans, blazers, tops, scarves and knit ties. It is building a cloud-based manufacturing platform to rapidly restock products “with very low risk in their inventory.

month. It produces a range of styles including sweaters, dresses, beanies, cardigans, blazers, tops, scarves and knit ties. It is building a cloud-based manufacturing platform to rapidly restock products “with very low risk in their inventory.

The company’s software facilities include a Shopify store that helps it to review order data for a new products, execute production and ship finished goods to customers in as little as five days. Its high-tech 3D-knitting machines reduce production waste, generating roughly 1 percent of the excess relative to other manufacturing techniques. The company offers a full-service solution for everything from yarn sourcing and knitting to finishing, packing and shipping. Its design template gives its clients new ideas while launching their designs if they don’t already have a style in mind.

Expanding its production model

Tailored has executed a pilot order for Gap Inc.’s new Hill City men’s active band—which could serve as a guinea pig for the Gap umbrella. As the company is being flooded with orders, it now plans to add 12 more knitting machines to its Brooklyn facility. However, its immediate plan includes opening a 100-machine factory in Brooklyn and expanding the lean production model to other close-to-customer regions surrounding the US coastline as it aims to make this location a model factory for other brands to emulate.