Monforts and its long-time partner, Bengal Technology and Engineering, have successfully installed over 100 fully integrated textile finishing lines in Bangladesh over the past 30 years. At the upcoming Dhaka International Textile & Garment Machinery Exhibition (DTG) from February 20-23, Monforts specialists will highlight the company’s latest innovations in sustainable fabric finishing.

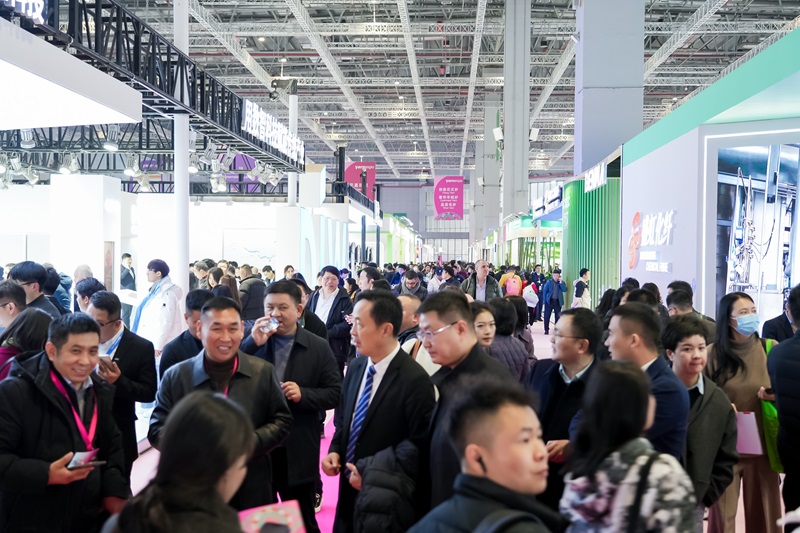

DTG, hosted at the International Convention City Bashundhara (ICCB), will feature over 1,000 global textile machinery brands from 31 countries. The event comes as Bangladesh’s textiles and apparel sector continues its rapid expansion, with over 6,000 factories now contributing to its status as the world’s second-largest exporter of readymade garments (RMGs). The government aims to boost RMG exports to $50 billion this year and $100 billion by 2030, making sustainable and efficient textile processing critical.

Monforts Head of Denim Hans Wroblowski emphasized the company’s commitment to reducing the CO₂ footprint of textile production. “Finishing is an energy-intensive process, and we have developed multiple solutions to optimize efficiency,” he said. Monforts Montex stenters widely used in denim and home textiles, offer high production throughput while ensuring significant energy savings.

Monforts latest innovations focus on energy efficiency, including the VarioMatex Padder for effective water removal, reducing drying costs, and the EcoApplicator, which uses kiss-roll technology for precise finishing in sportswear. The Universal Energy Tower improves heat recovery, cutting energy use by up to 25 per cent, while the ECO Booster System, integrated into Montex stenters, delivers up to 35 per cent energy savings.

These technologies can be retrofitted to existing lines, allowing manufacturers to upgrade without major investments. “With energy costs accounting for up to 70 per cent of production expenses, demand for energy-saving solutions is at an all-time high,” Wroblowski noted.

Monforts Thermex hotflue dyeing systems are widely used in Bangladesh, with over 900 installations worldwide. The Econtrol process, featured in 150 Thermex systems, enables rapid reactive dyeing in just two to three minutes, improving efficiency and sustainability.

Meanwhile, the MontexCoat coating unit is gaining traction in Bangladesh, with the first system installed at DBL Group. It offers versatile coating solutions, from full PVC coatings to minimal penetration treatments. Additionally, the coaTTex unit specializes in single-sided air knife and knife-over-roller coatings, making it a valuable addition for textile manufacturers.

“With strong interest in MontexCoat and coaTTex, we look forward to engaging with industry leaders at DTG,” Wroblowski added. “Bengal Technology and Engineering has been an excellent partner in Bangladesh, and together, we are ready to support the industry’s sustainable growth.”