Athletic apparel brand Lululemon has utlised the new enzymatic recycling process pioneered by Australian start-up Samsara Eco to design its new limited edition Packable Anorak Jacket.

Incorporating a mix of several materials, this groundbreaking jacket has been made from recycled plastic waste, end-of-life Lululemon apparel, and even converted carbon emissions.

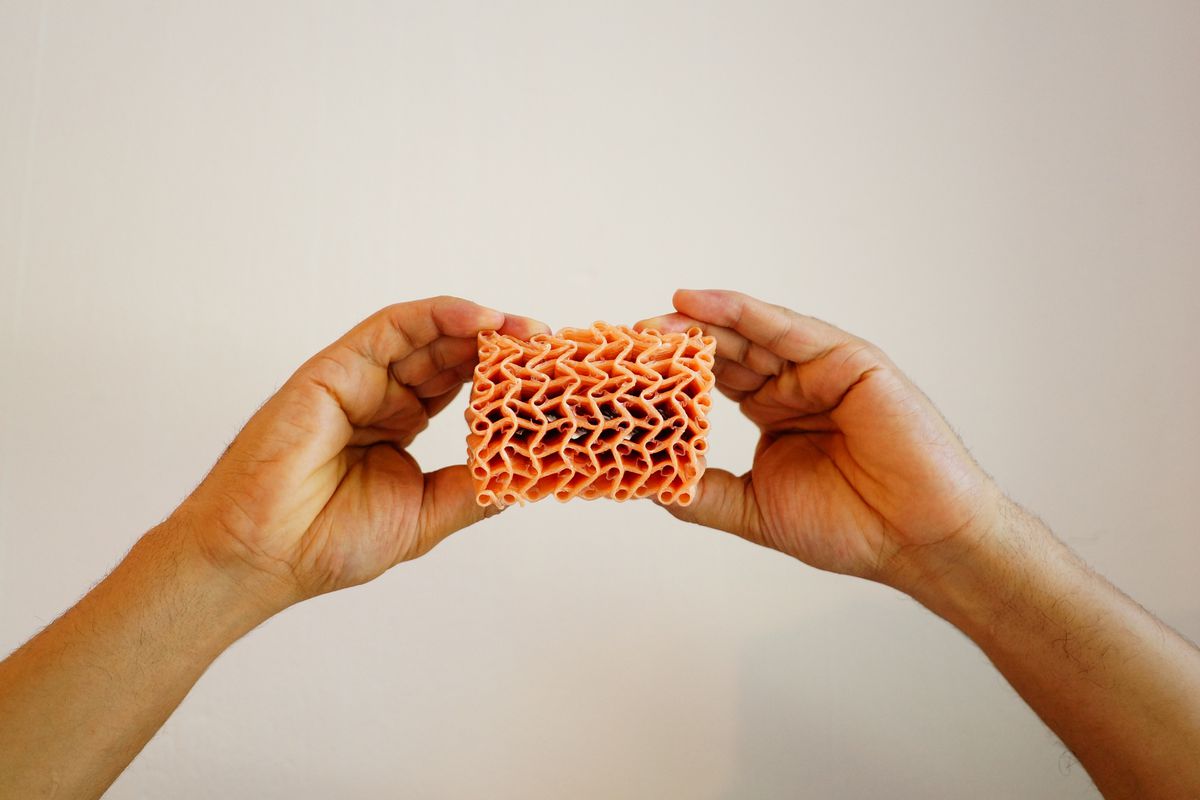

To produce this jacket, Samsara Eco employed its revolutionary low-temperature depolymerisation process. This process combines the elements of biophysics, chemistry, biology, and computer science to produce plastic-eating enzymes.

It is specifically optimised for PET, polyester, and nylon 66 recycling at scale and handles various blended fabric and mixed bale feedstocks, such as poly/cotton blends, nylon/elastane blends, carpet fibers, zip ties, and airbags.

In February too, Lululemon had collaborated with Samsara Eco to introduce enzymatically recycled polyamide 66 (PA66) apparel.

Yogendra Dandapure, Vice President-Raw Materials Innovations, Lululemon aims to expand these technologies to tackle textile waste across the entire supply chain. According to him, the capsule product is the first step in this journey, facilitating experimentation and learning as the company strives to advance circularity.